SMT Meaning Explained: From Assembly Process to the Diode Symbol on a PCB

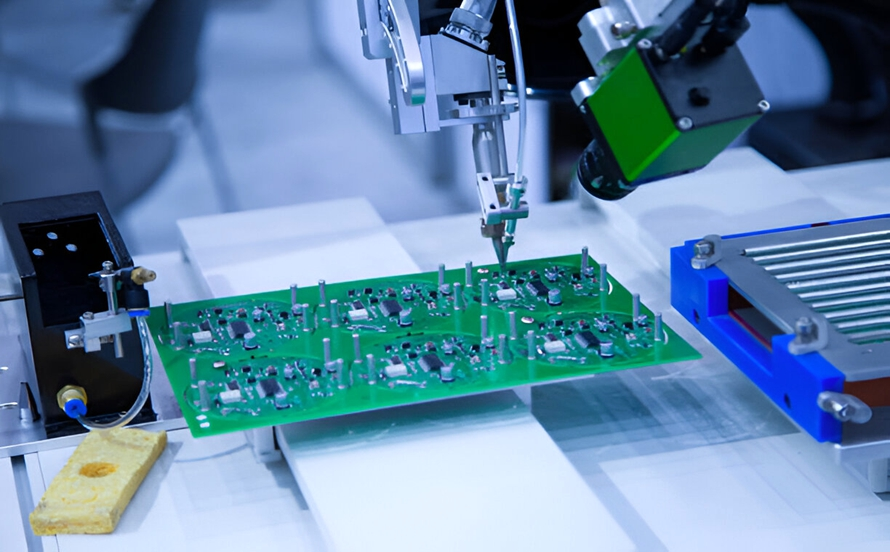

Surface Mount Technology is the foundation of modern electronics manufacturing.

To truly understand how electronic products are built today, it’s essential to start with a clear explanation of SMT meaning, and then connect that knowledge to how individual components—such as diodes—are represented and placed on a PCB using the correct diode symbol.

This article explains SMT from a manufacturing perspective and clarifies how diode symbols are used in circuit design and PCB assembly.

What Is the SMT Meaning in Electronics?

SMT stands for Surface Mount Technology.

In simple terms, SMT is a method of assembling electronic components by mounting them directly onto the surface of a printed circuit board (PCB), rather than inserting leads through drilled holes.

Key points behind the SMT meaning:

- Components are soldered on the PCB surface

- No through-hole insertion is required

- Enables high-density, compact circuit designs

- Supports automated, high-speed production

SMT has largely replaced traditional through-hole assembly in consumer electronics, industrial controls, automotive electronics, and communication devices.

Why SMT Became the Industry Standard

The rise of SMT is not accidental—it solves several manufacturing and design challenges at once.

Advantages of SMT:

- Smaller board size – critical for compact devices

- Higher component density – more functionality per PCB

- Better electrical performance – shorter signal paths

- Automated assembly – consistent quality and high throughput

- Lower cost at scale – ideal for mass production

Because of these advantages, understanding SMT meaning is a prerequisite for anyone involved in PCB design, sourcing, or assembly.

Common Components Used in SMT

SMT supports almost all modern electronic components, including:

- Resistors and capacitors (0402, 0603, 0805, etc.)

- Integrated circuits (SOP, QFN, BGA)

- Inductors and connectors

- Diodes, which play a key role in circuit protection and signal control

Among these, diodes are especially important—and that’s where the diode symbol becomes critical.

What Is a Diode Symbol?

A diode symbol is a standardized graphic used in circuit schematics to represent a diode and its electrical direction.

A diode allows current to flow in one direction only, and the symbol visually communicates this behavior.

Basic diode symbol explanation:

- Triangle or arrow-like shape → direction of current flow

- Vertical line (bar) → cathode

- The opposite side → anode

This symbol ensures that engineers, PCB designers, and SMT operators all interpret the component orientation correctly.

Why the Diode Symbol Matters in SMT Assembly

In SMT assembly, components are placed automatically by pick-and-place machines.

For polarized components like diodes, orientation is critical.

If a diode is placed in reverse:

- The circuit may not function

- Components can overheat or fail

- Entire PCB batches may be scrapped

That’s why the diode symbol used in the schematic must match:

- The PCB footprint

- The silkscreen marking

- The polarity indicator on the physical SMT diode

Common Diode Symbols You’ll See on SMT Designs

Different diode functions use slightly different symbols:

- Standard diode – basic current control

- Zener diode – voltage regulation

- Schottky diode – fast switching, low voltage drop

- LED symbol – diode with light emission arrows

Even though the physical SMT package may look similar, the symbol defines the electrical role of the diode in the circuit.

Connecting SMT Meaning with Diode Symbol in Real Production

Understanding SMT meaning is not just theoretical—it directly affects manufacturing outcomes.

In real SMT production:

- Engineers define the circuit using symbols (including diode symbols)

- PCB designers convert symbols into footprints

- SMT machines place diodes based on polarity data

- Reflow soldering permanently fixes the components

A small misunderstanding of a diode symbol can lead to:

- Incorrect polarity

- Functional failures

- Costly rework or delays

That’s why design accuracy and manufacturing discipline go hand in hand.

Conclusion: SMT Meaning Is More Than Assembly

To summarize:

- SMT meaning refers to mounting components directly on the PCB surface using automated processes

- SMT enables compact, high-performance electronic products

- The diode symbol is a critical communication tool between design and manufacturing

- Correct symbol usage ensures correct diode orientation and reliable PCB assembly

Whether you are reading schematics, designing PCBs, or reviewing SMT assembly files, understanding both SMT meaning and diode symbols is essential for building reliable electronics.

Post Comment