BGA PCB: Design, Manufacturing, and High-Density Performance

A BGA PCB is a printed circuit board specifically designed to support Ball Grid Array (BGA) components. BGA packages use an array of solder balls underneath the component instead of traditional leads, allowing for a much higher number of connections within a smaller footprint. This makes BGA PCBs essential for modern electronics that demand high performance, compact size, and reliable electrical connections.

As devices become more powerful and space-constrained, BGA PCB designs have become increasingly common in applications such as processors, memory modules, and high-speed communication equipment. These PCBs require precise design and manufacturing techniques to ensure reliable assembly and long-term performance.

Why BGA PCBs Are Critical in Modern Electronics

BGA components offer significant advantages in terms of electrical performance and packaging density. A BGA PCB enables shorter signal paths, reduced inductance, and improved power distribution compared to traditional leaded packages.

Because solder balls are distributed across the entire bottom surface of the component, heat and electrical current are spread more evenly. This improves thermal performance and reduces the risk of localized stress, making BGA PCBs ideal for high-speed and high-power electronic systems.

Structure and Layout of a BGA PCB

The structure of a BGA PCB typically involves multilayer construction with carefully planned signal, power, and ground layers. Fine-pitch routing is required to fan out the solder balls from the BGA component to inner and outer layers of the board.

Microvias, blind vias, and buried vias are commonly used in BGA PCB designs to accommodate high pin counts without increasing board size. Proper layer stack-up and via design are critical to maintaining signal integrity and ensuring manufacturability.

Advantages of Using BGA PCBs

One of the main advantages of BGA PCBs is high interconnection density. They allow designers to place more functionality into smaller spaces, which is essential for compact consumer electronics and advanced computing systems.

BGA PCBs also provide improved electrical performance. Shorter interconnections reduce signal delay and electromagnetic interference, making them suitable for high-speed applications. In addition, the solder ball interface offers better mechanical reliability compared to traditional leads, especially under thermal cycling.

From an assembly standpoint, BGA components support automated placement and reflow soldering, enabling efficient mass production when properly designed.

Common Applications of BGA PCBs

BGA PCBs are widely used in consumer electronics such as smartphones, laptops, gaming consoles, and wearable devices. Processors, GPUs, and memory chips often rely on BGA packaging to achieve high performance in limited space.

In telecommunications and networking equipment, BGA PCBs support high-speed data processing and signal routing. Automotive electronics, including infotainment systems and advanced driver assistance systems, also use BGA PCBs for their reliability and compact design.

Industrial control systems, medical devices, and aerospace electronics further benefit from the performance and durability of well-designed BGA PCBs.

BGA PCB vs Traditional PCB Designs

Compared to traditional PCB designs using through-hole or leaded surface-mount components, BGA PCBs offer significantly higher connection density and better electrical characteristics. Traditional packages can struggle with signal integrity as pin counts increase, while BGA designs scale more efficiently.

However, BGA PCBs are more complex to design and manufacture. Inspection and rework are also more challenging because solder joints are hidden beneath the component. Despite these challenges, the performance benefits of BGA PCBs make them the preferred choice for advanced electronic systems.

Key Design Considerations for BGA PCBs

Designing a BGA PCB requires careful attention to pad layout, via placement, and trace routing. Fan-out strategies must be optimized to route signals efficiently while avoiding congestion.

Thermal management is another critical consideration. Proper use of thermal vias and copper planes helps dissipate heat generated by high-power BGA components. Signal integrity analysis is essential to minimize issues such as crosstalk and impedance mismatch.

Close collaboration between PCB designers and manufacturers during the design phase helps ensure that the layout is both high-performing and manufacturable.

Manufacturing Challenges in BGA PCBs

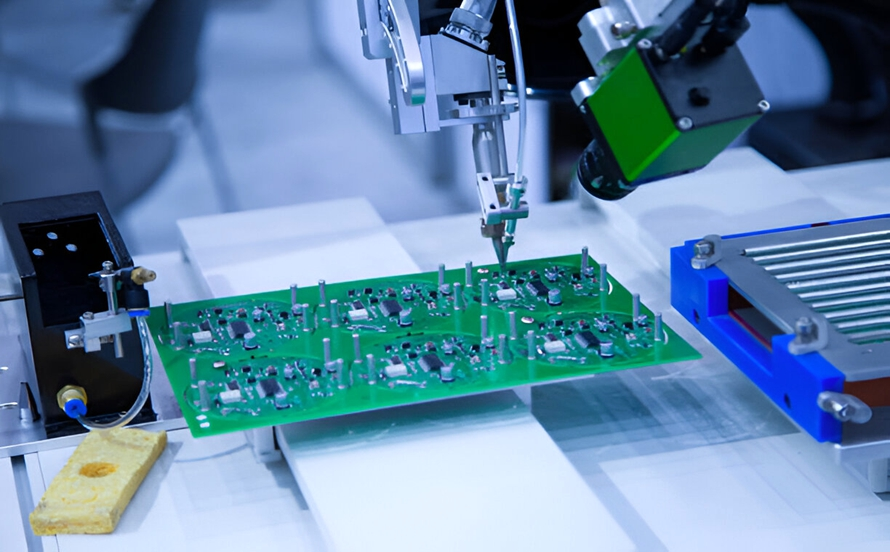

Manufacturing BGA PCBs involves tight tolerances and advanced fabrication techniques. Fine-line etching, precise drilling, and accurate layer alignment are essential to meet design requirements.

Assembly processes such as solder paste printing, component placement, and reflow soldering must be carefully controlled to avoid defects like solder bridging or voiding. Inspection methods such as X-ray inspection are commonly used to verify solder joint quality since joints are not visible externally.

Due to these complexities, BGA PCB manufacturing requires specialized expertise and robust quality control systems.

Importance of Testing and Inspection

Testing plays a vital role in ensuring the reliability of BGA PCBs. Electrical testing verifies connectivity, while X-ray inspection helps detect hidden solder defects under BGA components.

Thermal cycling and reliability testing are often used for high-reliability applications to ensure that solder joints can withstand temperature variations over time. These testing processes help identify potential issues early and improve overall product quality.

How to Choose the Right BGA PCB Manufacturer

Selecting the right BGA PCB manufacturer is crucial for achieving consistent quality and reliable performance. A qualified manufacturer should have experience with fine-pitch BGA designs, multilayer boards, and advanced assembly processes.

Look for a manufacturer that offers design-for-manufacturing support, advanced inspection capabilities, and strict quality control standards. Experience in handling complex BGA layouts and high-volume production is a strong indicator of reliability.

A professional manufacturing partner can help reduce risks, improve yields, and ensure smooth transition from prototype to mass production.

Final Thoughts

BGA PCBs have become a cornerstone of modern electronics, enabling compact designs, high-speed performance, and reliable interconnections. While they require advanced design and manufacturing expertise, their benefits far outweigh the challenges for high-density and high-performance applications.

If your project involves complex layouts and demanding performance requirements, partnering with an experienced bga pcb manufacturer is essential. The right manufacturing partner will help deliver high-quality, production-ready BGA PCBs that meet today’s strict technical and reliability standards.

Post Comment